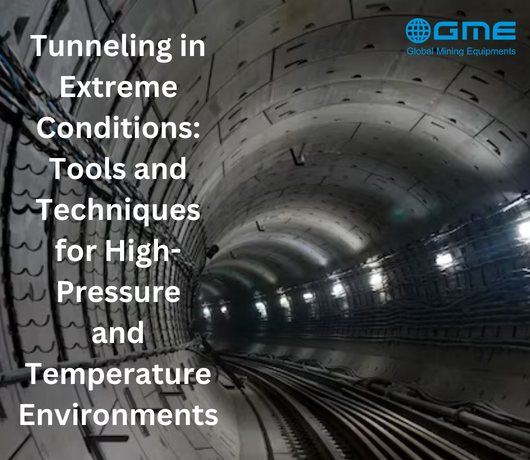

Tunnel construction is a challenging feat of engineering, particularly when it involves high-pressure and extreme temperature conditions. These environments demand not only specialized techniques but also a set of robust tunnel construction tools. In this blog, we delve into the essential tools and techniques that make tunneling possible in these demanding circumstances.

Mastering the Depths: Key Tools for High-Pressure Tunnelling

One of the primary challenges in tunnel construction under high-pressure conditions is maintaining the structural integrity of the tunnel while dealing with the immense force exerted by the surrounding earth or rock. This is where tools like the jackleg and stoper drill come into play.

Jackleg Drill: This versatile tool is crucial for drilling in confined spaces. Its design allows for drilling in various angles, which is essential for precision work in tunnel construction. In high-pressure environments, the jackleg drill’s ability to bore holes for explosives or reinforcement rods becomes invaluable.

Stoper Drill: Similar to the jackleg, the stoper drill is used for drilling, but it’s typically employed in vertical or overhead drilling applications. In high-pressure situations, the stoper drill’s ability to create holes for anchors and bolts ensures the safety and stability of the tunnel structure.

Braving Extreme Temperatures: Advanced Tunneling Equipment

Tunneling in environments with extreme temperatures, whether scorching hot or freezing cold, requires equipment that can withstand these harsh conditions.

Lubricator: Essential for the maintenance and longevity of pneumatic tools, the lubricator plays a critical role in tunnel construction. It ensures that tools like drills and drifters operate smoothly, even in extreme temperatures, by providing a steady flow of oil, which reduces the wear and tear caused by high temperatures or friction.\

Pneumatic Drifter: This powerful drilling tool is widely used in tunnel construction for its efficiency and effectiveness in hard rock drilling. In extreme temperature conditions, its pneumatic nature makes it more reliable than electrically powered tools, which may falter in such environments.

Hydraulic Drifter: As an alternative to the pneumatic drifter, the hydraulic drifter offers enhanced power and efficiency, particularly beneficial in hard-rock conditions. Its hydraulic system is less susceptible to temperature fluctuations, making it a preferred choice in environments where extreme temperatures can affect the performance of pneumatic systems.

In conclusion, the success of tunnel construction tools in high-pressure and extreme temperature conditions hinges on the selection and utilization of appropriate tools. The integration of tools like the jackleg, stoper drill, lubricator, pneumatic drifter, and hydraulic drifter is not just about efficiency; it’s about ensuring the safety and viability of the entire tunneling project. As technology advances, we can expect even more innovative tools and techniques to emerge, further pushing the boundaries of what’s possible in extreme tunnel construction scenarios.