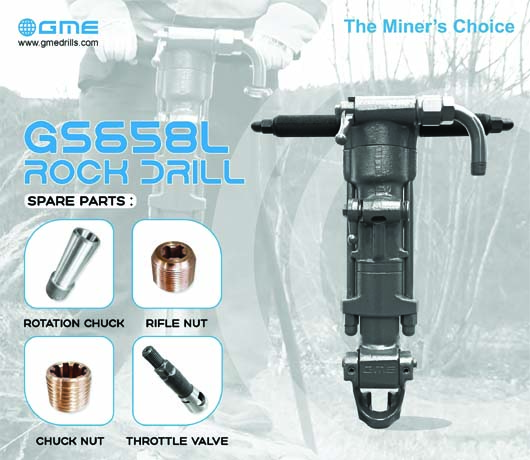

In the realm of rock excavation and mining, precision and power are paramount. One tool that stands out in the league of heavy-duty equipment is the Sinker Rock Drill. Tailor-made for drilling through hard-faced rock, granite, and other formidable terrains, these drills play a crucial role in bench drilling, quarry drilling, and creating secondary holes for blasting operations. In this blog, we’ll explore the features and components that make the Sinker Rock Drill an indispensable asset in the world of rock excavation.

Precision Components:

1. Rotation Chuck:

At the heart of the Sinker Rock Drill lies the Rotation Chuck – a component that facilitates the rotation of the drill bit. This precision-engineered part ensures that the drill bit can effectively cut through the toughest rocks, providing the necessary torque and rotation needed for optimal performance.

2. Rifle Nut:

The Rifle Nut is a key component that enhances the stability and alignment of the drill. Its unique design helps maintain accuracy during the drilling process, allowing operators to achieve precise results even in challenging geological conditions. This component is a testament to the engineering excellence behind Sinker Rock Drills.

3. Chuck Nut:

Playing a crucial role in securing the drill bit in place, the Chuck Nut is another essential component of the Sinker Rock Drill. Its robust design ensures a tight grip on the drill bit, preventing any slippage during operation. This level of reliability is crucial when dealing with hard rock surfaces.

4. Throttle Valve:

Control is key in any drilling operation, and the Throttle Valve is the component that provides it. This part allows operators to regulate the air or hydraulic pressure, fine-tuning the drilling process based on the hardness of the rock. The Throttle Valve ensures efficiency and safety, enabling precise drilling with minimal waste.

Applications:

1. Bench Drilling:

Sinker Rock Drills are specifically designed for bench drilling applications, where accuracy and precision are non-negotiable. Whether it’s a mining site or a construction project, these drills excel in creating perfectly aligned holes for various purposes.

2. Quarry Drilling:

In the challenging environment of a quarry, Sinker Rock Drills shine. Their ability to penetrate hard-faced rock and granite makes them indispensable for extracting raw materials efficiently and safely.

3. Secondary Holes for Blasting:

Creating secondary holes for blasting requires a drill that can handle tough rocks with ease. Sinker Rock Drills are tailored for this purpose, ensuring that the blast patterns are executed according to plan.

In the world of rock excavation, Sinker Rock Drills are the epitome of precision, power, and reliability. With components like Rotation Chuck, Rifle Nut, Chuck Nut, and Throttle Valve, these drills are engineered to conquer the toughest terrains. From bench drilling to quarry operations and secondary holes for blasting, the Sinker Rock Drill is a true workhorse, setting the standard for excellence in the field of hard rock drilling.